MECHANICAL AND FABRICATION

Industry Type:�Food Production

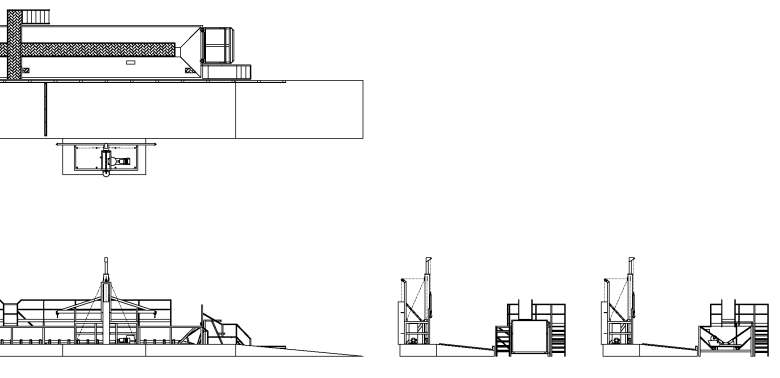

Project Description:�As-Build Bulk Delivery System

Disciplines Involved:�Survey, Structural

Bulk Onion Delivery System is being duplicated at another facility. The scope required Cadmaster Tech to reverse engineer the entire delivery system including the truck approach path. We developed detailed site plan, sections, details, and traffic patterns based on the existing system. Additional work was put into the new design to improve worker functionality and safety.

Key Project Responsibilities and Skills:

- As-Build Surveying

- 3D-Modeling

- Detailed Structural Drawings

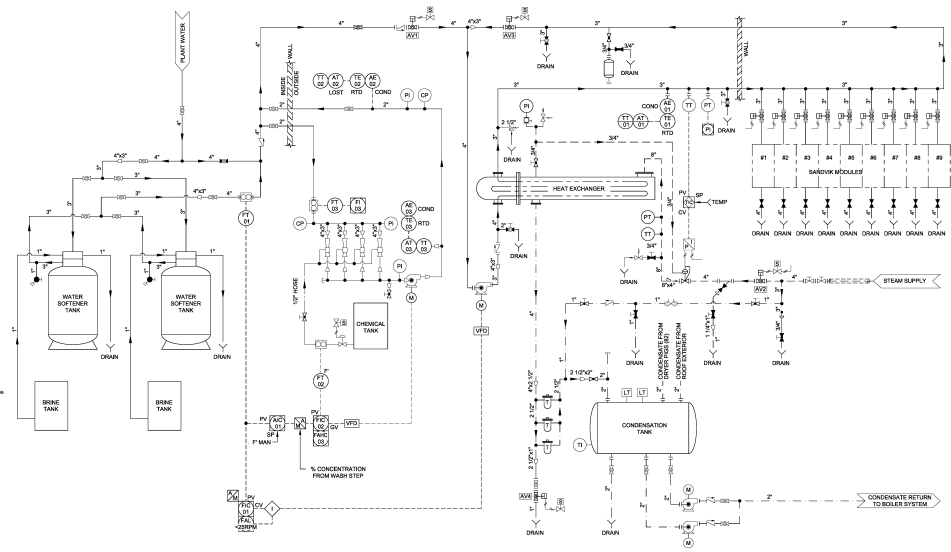

Industry Type:�Wet Onion Line

Project Description:�Survey CIP System������

Disciplines Involved: Survey, P&ID

New CIP system needed to be recorded for documentation into the master CAD system. It was determined that a P&ID was sufficient for the As-Build. Special precautions were taken to work around the wet onion line. Survey was able to be performed without interruption to production line.

Key Project Responsibilities and Skills:

- Survey

- P&ID

- Safety

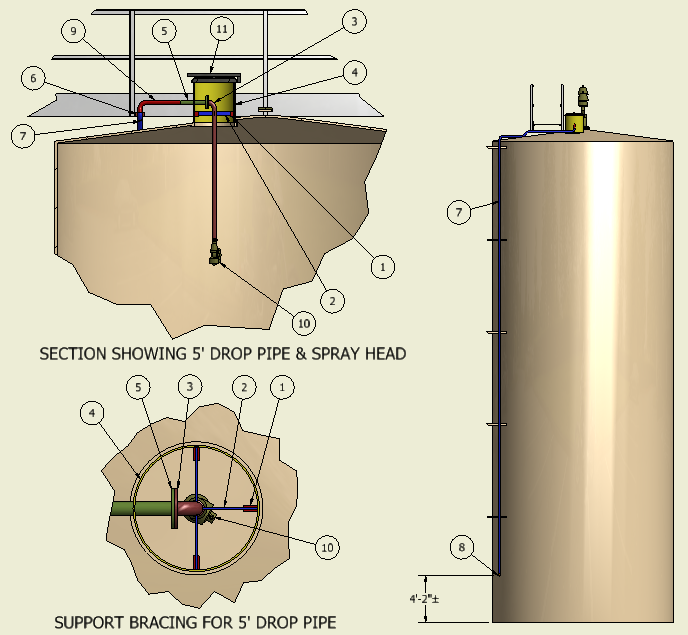

Industry Type:�Winery

Project Description:�CIP System������

Disciplines Involved: Assembly Drawings

New CIP system was designed and built on-site for large wine storage tanks. The pieces were on the ground and the client wanted assembly drawings created. We decided that 3D assembly drawings were easier for the construction crew to read and we handed over 3D PDF's to reduce confusion on the assembly.

Key Project Responsibilities and Skills:

- Assembly Drawings

- 3D Modeling

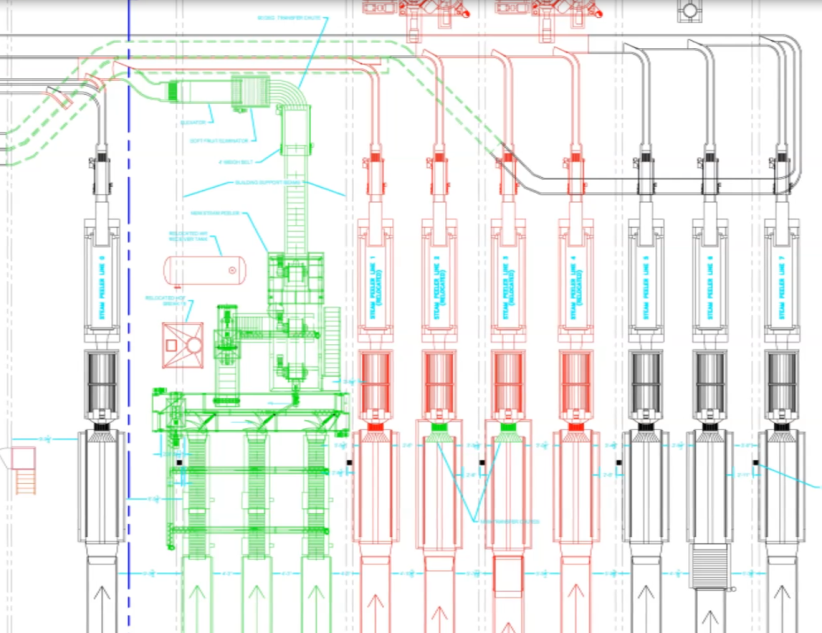

Industry Type:�Onion & Garlic

Project Description:�As-Build Bulk Delivery System

Disciplines Involved:�Survey, Product Conveyance

Upgrades to the bulk delivery system have been made over many years without proper documentation of the entire system. Cadmaster Tech surveyed the equipment and platform which extended from ground to a height of 60 feet. 2D Plan View drawings were sufficient for client to update necessary CAD system. The Wet Garlic line was also added to the scope to capture all equipment located in this part of the building. Future plans for expansion required good survey of all systems in the room including the drainage system.

Key Project Responsibilities and Skills:

- Survey

- Structural

- 2D General Layout

- Understanding of Conveyance System

Industry Type:�Tomato Canning

Project Description: Create Conveyance Line Mapping

Disciplines Involved: Product Conveyance, Work Flow Mapping

There are over 30 choices for the bulk delivery water chute system to deliver product to the canning lines. Simple maps were created for every option that operators face when selecting a delivery chute to a production line. Work Flow Mapping helped refine operations and management to ensure proper delivery of the product to the correct canning line.

Key Project Responsibilities and Skills:

- Conveyance Systems

- Work Flow Diagrams