EQUIPMENT LAYOUT

Industry Type:�Food Production

Project Description:�As-Build 4 Rooms and Platform

Disciplines Involved:�Structural

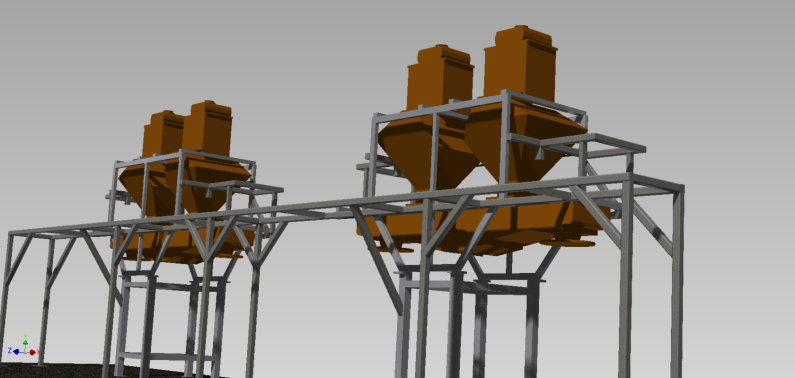

4 adjoining rooms shared structural steel platforms supporting onion powder equipment. The platform was built first and then the rooms were added with the platform protruding through the walls. The client needed detailed structural information and accurate drawings to calculate the load of additional equipment being added to the platforms. It was determined that 3D modeling using Inventor Frame Generator would best serve the Structural Engineers needs.

Key Project Responsibilities and Skills:

- As-Build Surveying

- 3D-Modeling

- Detailed Structural Drawings

Industry Type:�Food Production

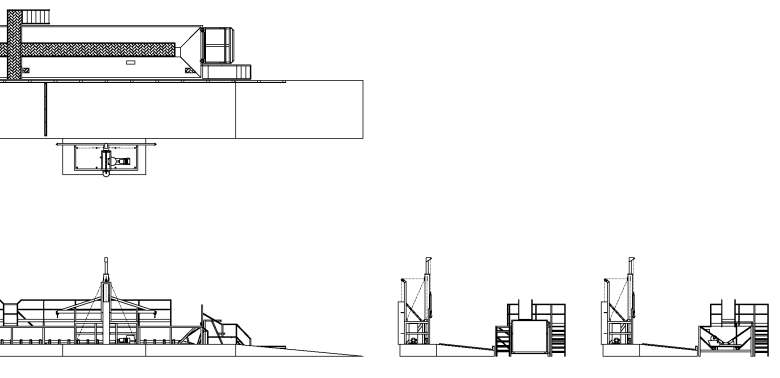

Project Description:�As-Build Bulk Delivery System

Disciplines Involved:�Survey, Structural

Bulk Onion Delivery System is being duplicated at another facility. The scope required Cadmaster Tech to reverse engineer the entire delivery system including the truck approach path. We developed detailed site plan, sections, details, and traffic patterns based on the existing system. Additional work was put into the new design to improve worker functionality and safety.

Key Project Responsibilities and Skills:

- As-Build Surveying

- 3D-Modeling

- Detailed Structural Drawings

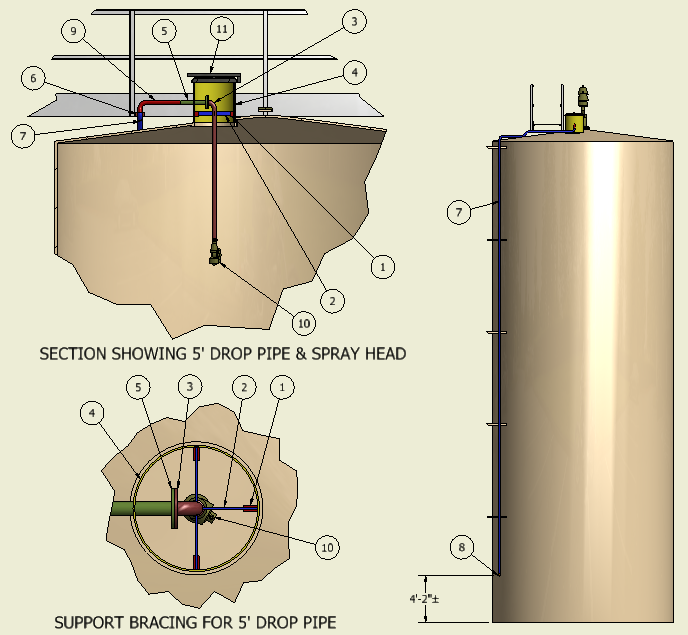

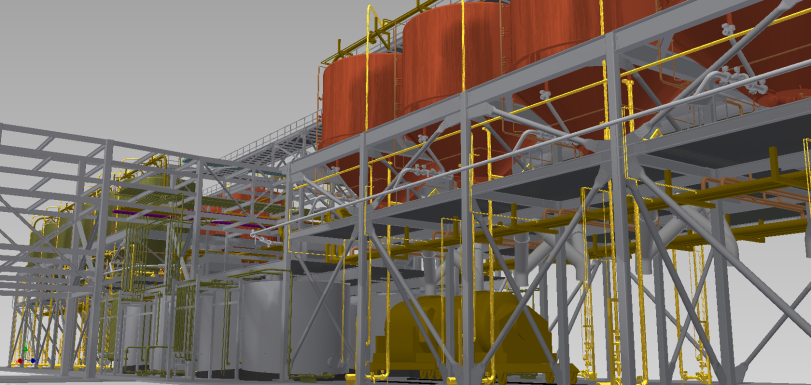

Industry Type:�Winery

Project Description:�CIP System������

Disciplines Involved: Assembly Drawings

New CIP system was designed and built on-site for large wine storage tanks. The pieces were on the ground and the client wanted assembly drawings created. We decided that 3D assembly drawings were easier for the construction crew to read and we handed over 3D PDF's to reduce confusion on the assembly.

Key Project Responsibilities and Skills:

- Assembly Drawings

- 3D Modeling

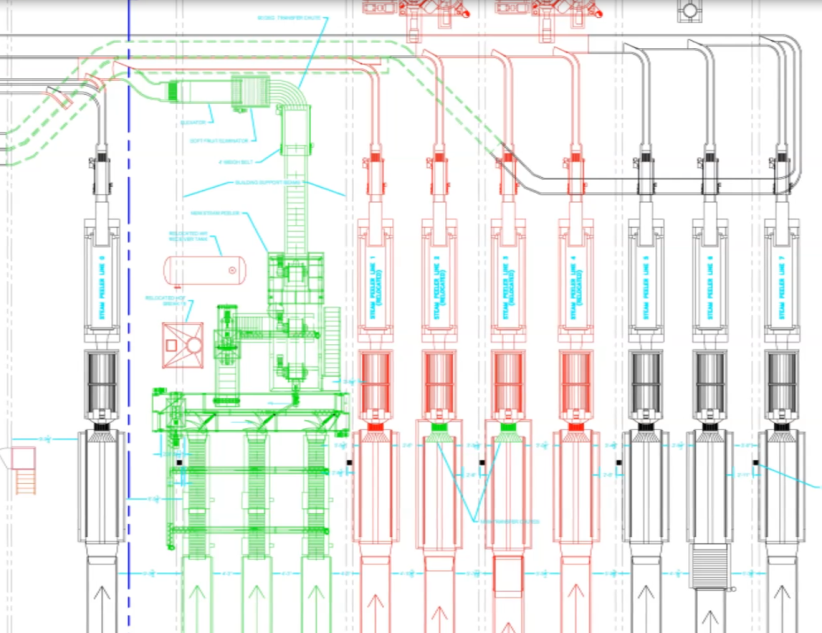

Industry Type:�Onion & Garlic

Project Description:�As-Build Bulk Delivery System

Disciplines Involved:�Survey, Product Conveyance

Upgrades to the bulk delivery system have been made over many years without proper documentation of the entire system. Cadmaster Tech surveyed the equipment and platform which extended from ground to a height of 60 feet. 2D Plan View drawings were sufficient for client to update necessary CAD system. The Wet Garlic line was also added to the scope to capture all equipment located in this part of the building. Future plans for expansion required good survey of all systems in the room including the drainage system.

Key Project Responsibilities and Skills:

- Survey

- Structural

- 2D General Layout

- Understanding of Conveyance System

Industry Type:�Tomato Canning

Project Description: Create Conveyance Line Mapping

Disciplines Involved: Product Conveyance, Work Flow Mapping

There are over 30 choices for the bulk delivery water chute system to deliver product to the canning lines. Simple maps were created for every option that operators face when selecting a delivery chute to a production line. Work Flow Mapping helped refine operations and management to ensure proper delivery of the product to the correct canning line.

Key Project Responsibilities and Skills:

- Conveyance Systems

- Work Flow Diagrams

Industry Type:�Winery

Project Description: Replace Distillation System

Disciplines Involved:�Project Management, Surveying, Mechanical, Structural, Civil, Plant Operations

Distillation system is being upgraded from the ground up while utilizing the existing 6 story structure. It was important to survey and As-Build the entire system and adjoining area. The project took place in two phases to keep operations running. This is a multi-discipline project that Cadmaster Tech was contracted to run Project Management Modeling to control the General Arrangement and produce a model capable of clash detection. The 70 foot tall tanks contained over 100 nozzles each and required close contact with the still manufacturer to ensure the stills would fit in the existing structure. The footings needed to be enlarged to bring the existing structure into compliance with existing regulations. A 7th level was added to the still structure to accommodate the larger tanks.

For the project to be a success it was important to pay close attention to operations and maintenance. The area is considered a high explosive risk area because they produced 180 proof alcohols in large volumes. Safety showers, high viz tape and extra lighting was added to the area to increase safety of the workers. Opportunities were taken to use existing steel channels to brace heavy lids for easier maintenance of the condenser tanks.

As-Build required more than just updating the existing P&ID's and Site Plans. The drawings were very old and out of date. There have been dozens of upgrades to the entire plant that react with the distillation system. A full review of the historic documents dating back to the late 1960's was required to put the full picture of underground utilities together.

Key Project Responsibilities and Skills:

- Project Management

- Surveying

- Site Planning

- Mechanical P&ID's

- Civil

- Underground Utilities

- Structural

- 3D-Modeling

- Navisworks for Clash Detection

- Research

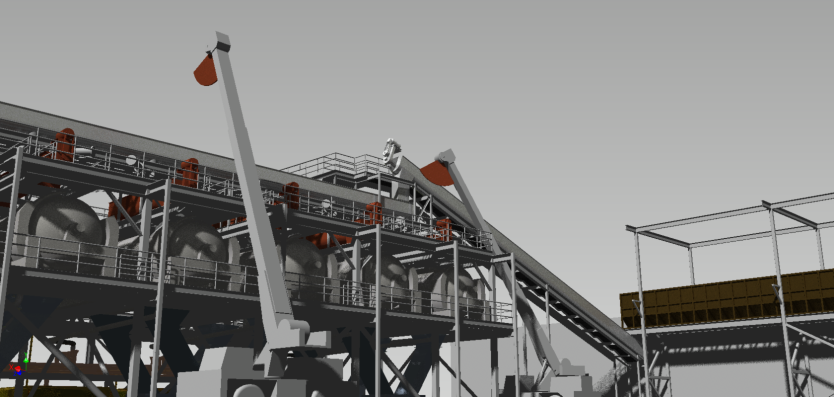

Industry Type:�Winery

Project Description:�Bulk Dump and Fermentation System

Disciplines Involved:�Project Management Modeling

Cadmaster Tech was contracted to take engineering plans from multiple companies and create a master model for clash detection. We modeled from the bulk dump system to a 24 tank system with 2 massive bladder presses on rail road tracks below the fermenter tanks. There were several screw conveyors and a large pipe rack and tower that traveled through the fermenter structure. This was a complex system laced with pipes. We were able to identify several clashes and give design suggestions to reduce change orders and save the client time and money.

Key Project Responsibilities and Skills:

- 3D-Modeling

- Project Coordination

- Value Engineering

Industry Type:�Winery

Project Description:�Bulk Dump and White Wine Press System

Disciplines Involved: Project Management Modeling

Cadmaster Tech was contracted to take engineering plans from multiple companies and create a master model for clash detection. We modeled from the bulk dump system to a structure containing 6 large bladder presses. There were several screw conveyors and stairs that had to function around the main platform. We also helped in the design of a delivery system to take product from any press to any storage tank below the structure. We were able to identify several clashes and give design suggestions to reduce change orders and save the client time and money.

Key Project Responsibilities and Skills:

- 3D-Modeling

- Project Coordination

- Value Engineering